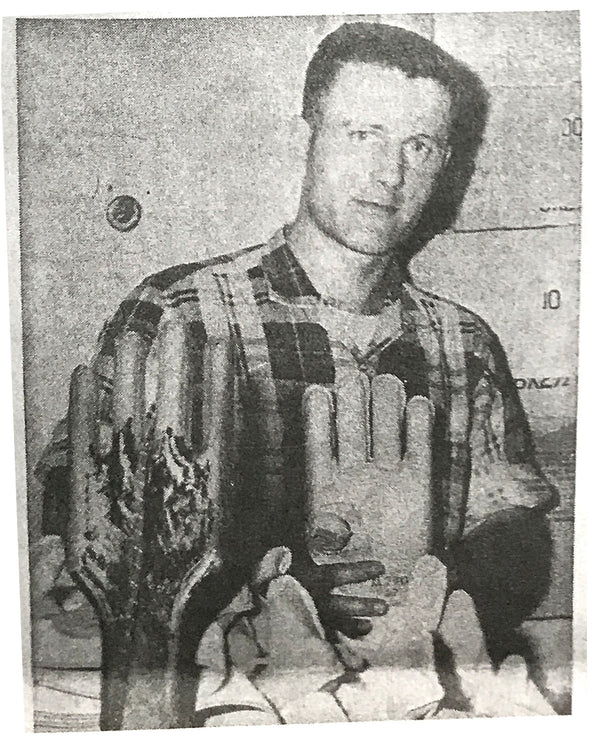

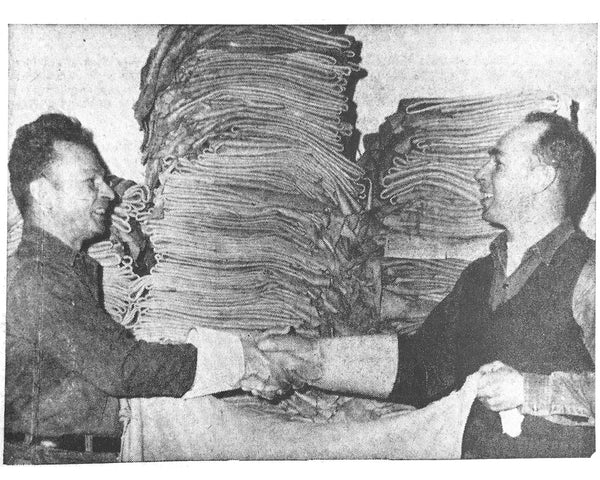

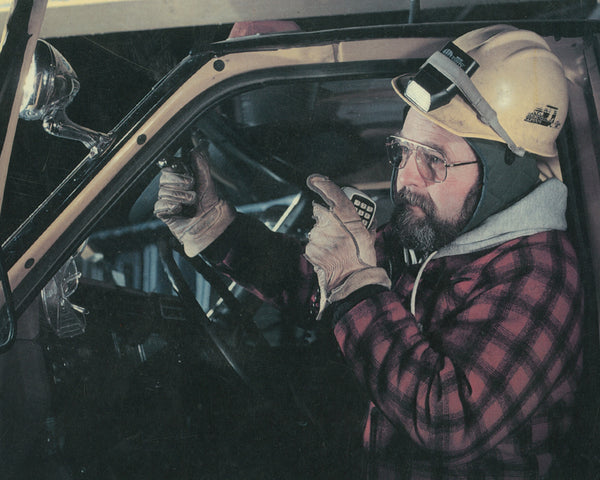

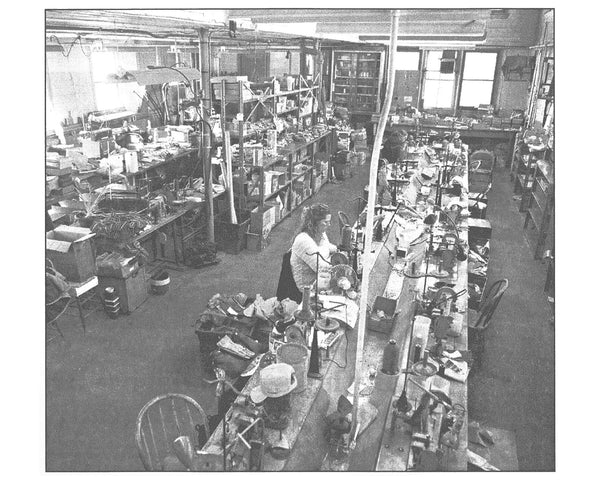

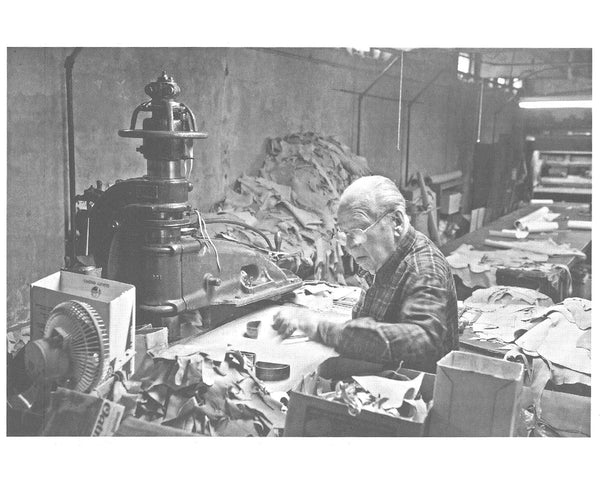

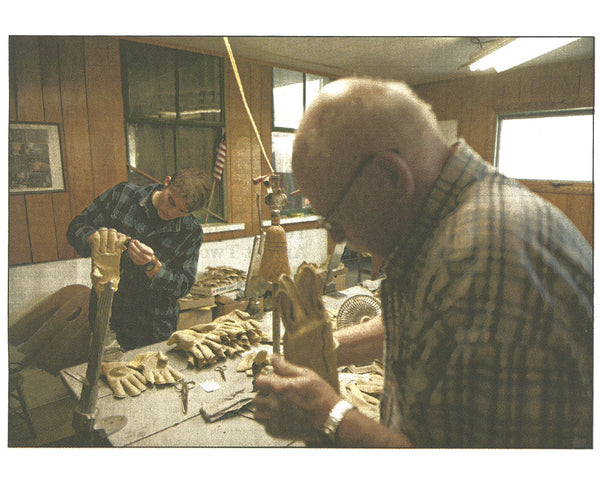

ACTUALLY MADE IN

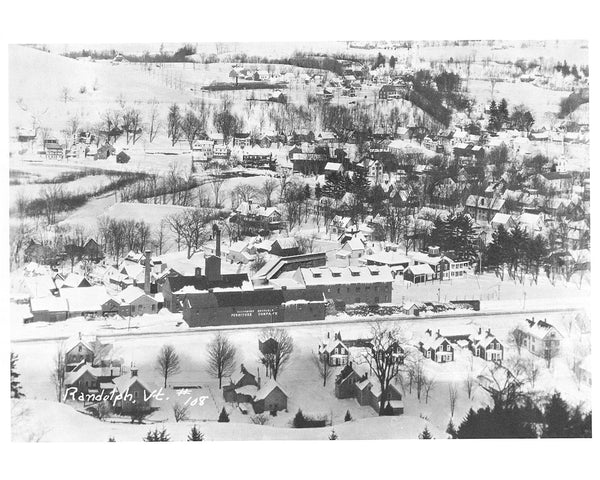

RANDOLPH, VERMONT SINCE 1920

2019

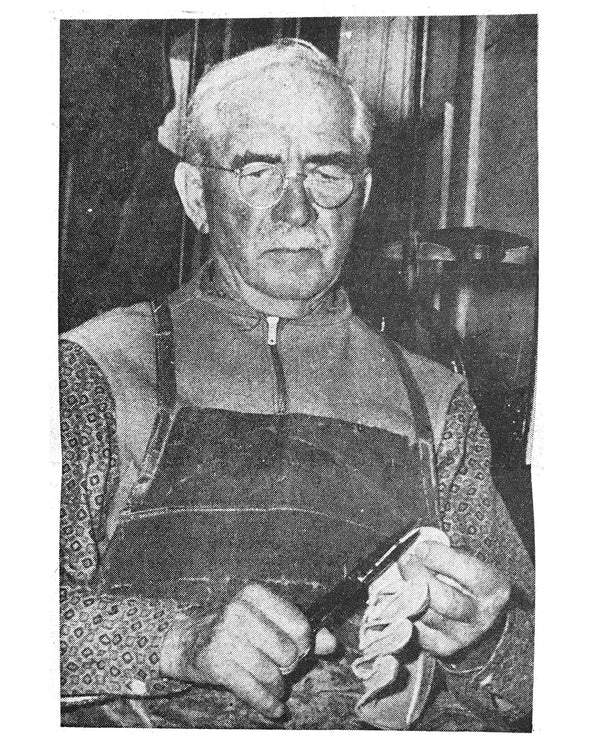

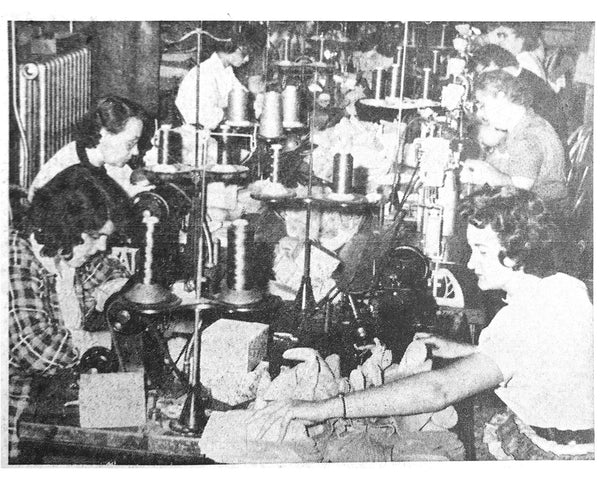

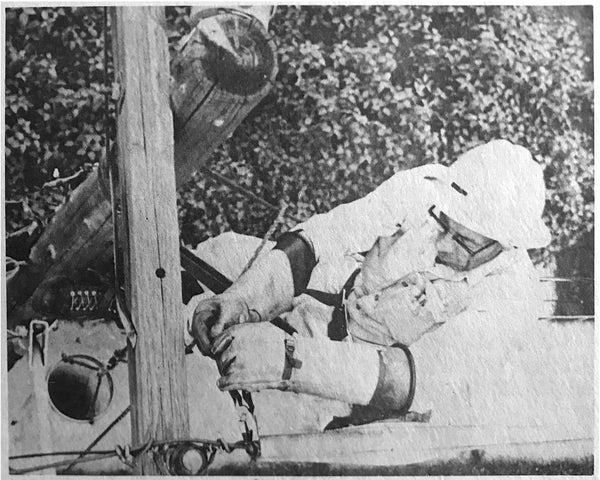

GMGCo. becomes Vermont Glove, leverages current product line to reach new trades and consumers, transitions glove factory to run on 100% renewable energy, invests in operational efficiency, while continuing to use existing machinery from the 1920’s - 1950’s. Positions company for growth through sales & marketing efforts.